General ClO2 Information and Use Benefits

Gas

StayFresh APS products produce ClO2 gas. When used, the gas widely penetrates facilities and effectively seeks out areas often overlooked in sanitation programs. This is especially important in HVAC systems that control the flow of air in a facility. It is also especially important in hard to reach areas and in areas where porous surfaces, chain link fencing, cracks, crevices and other surfaces are often overlooked in a routine cleaning program.

ClO2 AS A BIOCIDE

Chlorine dioxide is widely recognized as being a highly effective biocide with superior efficacy against viruses, spore forming bacteria, and fungi, as well as protozoan parasites like giardia and cryptosporidium. It was the principal agent of choice used by the US Government in the decontamination of buildings after the 2001 Anthrax attacks. ClO2 has also been shown to be an effective agent at combating airborne pathogens at concentrations well below permissible OSHA human exposure levels and is therefore considered by numerous studies to be a useful preventative against various airborne pathogens. In addition, ClO2 has been shown to have synergistic effects when used in combination with disinfecting agents enhancing the overall effectiveness of sanitation regiments. (We are making no such claims on our labeling)

ClO2 AND BIOFILM

Biofilms house a variety of pathogens and are hard to penetrate. Not surprisingly it has been found that substantially longer contact times and/or much higher concentrations of biocides are required than generally recognized to reach organisms hidden in these biofilms. Because of its mechanism of action and its affinity for water, studies have shown ClO2 is particularly effective at removing and controlling biofilms, thus exposing organisms, and making overall disinfection more effective. (We are making no such claims on our labeling)

ENVIRONMENTALLY SPARING

Unlike Chlorine, ClO2 does not adversely react with organic compounds and as a result does not produce unwanted carcinogenic chlorinated volatile organic compounds (V.O.C.s) and trihalomines. In fact, instead of combining with the aromatic rings of organic compounds, ClO2 actually breaks these rings apart reducing levels of chlorinated organics. This makes ClO2 use environmentally sparing! Also, because ClO2 does not react or combine with organic compounds, much more of it remains available to do its job. KennelSol® APS products are biodegradable, decomposing in sunlight and heat into nothing more than salt.

HVAC SYSTEMS

Because ClO2 has a high affinity for moisture it seeks out and penetrates areas where viruses, bacteria, and molds congregate. This is especially important in HVAC systems that control the flow of air in animal care facilities.

ISOLATION ROOMS

Because chlorine dioxide has been shown to be an effective agent at combating airborne pathogens it makes it an ideal consideration for use in isolation wards where airborne pathogen disease transmission is a concern. (We are making no such efficacy statements and or claims on our labeling)

ODOR * ELIMINATION

Because ClO2 breaks down the aromatic rings of various organic compounds it makes it a superior odor eliminator by destroying odors at their source. It is effective on all animal associated odors like feces, urine, and vomit, as well on other unwanted odors like mold, mildew, skunk, and even smoke.

FACILITY SPARING

ClO2 is less corrosive than chlorine and almost negligible at use concentrations, and has a neutral pH.

Revision Date: March 30, 2012

Study of ClO2 Levels in Room Treated with StayFresh™ APS Room “Shock” Deodorizer

L. Sheela Logan

Executive Summary

Common indoor odors vary greatly in type and source. Many products currently on the market can successfully remediate a narrow range of odor sources at best, or simply mask the scents with fragrances. Alpha Tech Pet, Inc. has designed a product that addresses this problem: StayFresh APS (air purification system) Room “Shock” Deodorizer. Air quality improvement is accomplished by the controlled release of ClO2, a compound with demonstrated effectiveness in destroying a wide range of common facility odors as well as their microbial sources.

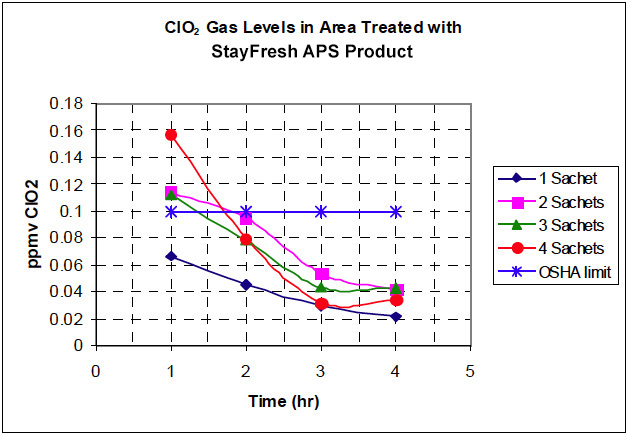

A number of adverse health effects may result from exposure to high levels of ClO2. OSHA has set safe exposure limits of 0.3 ppm for 15 minutes and a time-weighted average of 0.1 ppm for 8 hours of contact with ClO2 gas. To ensure compliance with OSHA standards, treatment tests were conducted and air samples analyzed for ClO2 levels.

Results from air sample analysis show that, at all dosage levels applied in this experiment, the concentration of ClO2 in the room was well below 0.1 ppm for the 4-hour treatment duration. ClO2 levels declined rather than accumulated over time—indication of the consumption and degradation of this compound.This experiment demonstrates that the Room “Shock” Deodorizer is safe for human exposure.

Background

Alpha Tech Pet, Inc. has developed StayFresh APS Room “Shock” Deodorizer, a ClO2-releasing product that destroys common facility malodors, such as those caused by fouled air conditioning, smoke, spills and pets. Excessive exposure to ClO2 gas can cause irritation of the eyes and respiratory tract. In severe cases, pulmonary edema or chronic bronchitis may result. The Occupational Health & Safety Administration (OSHA) has established ClO2 exposure limits of 0.3 ppm (0.83 mg/m3) for 15 minutes and the time-weighted average of 0.1 ppm (0.28 mg/m3) for 8 hours of exposure.

Experiments were conducted to determine, at varied dosage levels, the ClO2 concentrations in a treated room, and to ensure that this product, when used as prescribed, complies with OSHA standards.

Ion chromatography is the standard method used by OSHA in the detection and quantification of ClO2; however, when ClO2 is present in samples at visibly detectable levels, titrimetry serves as an effective analytical tool.

Materials/Procedures

SKC 224XR Series flow pump, StayFresh APS Room “Shock” Deodorizer ClO2 gas-phase sachets, 10 wt % potassium iodide solution (KI), distilled water, standard laboratory glassware

For each experiment, 10 mL of potassium iodide solution (KI) was placed in each impinger. The air sample collection apparatus (see Figure 1) and sachets were placed in the closed-off treatment room. ClO2 gas-phase sachets were activated by unfolding and shaking vigorously for a few seconds for the thorough mixing of materials, followed by suspension of the sachets from ceiling vents. The flow pump power button was immediately switched to ON, and the air flow rate recorded. The flow pump rate through the impingers was 2.3 L/min for all experiments.

Figure 3: StayFresh APS ClO2 sachets suspended from ceiling vent

Results

Twenty-one treatment experiments with StayFresh APS Room “Shock” Deodorizer were conducted in a two-month span. The individual data points are referenced in the Appendix (see Table 2). Average ClO2 levels in the room air space, presented as parts-per-million-by-volume (ppmv), are displayed in Table 1. This data is presented in graphical form in Figure 4.

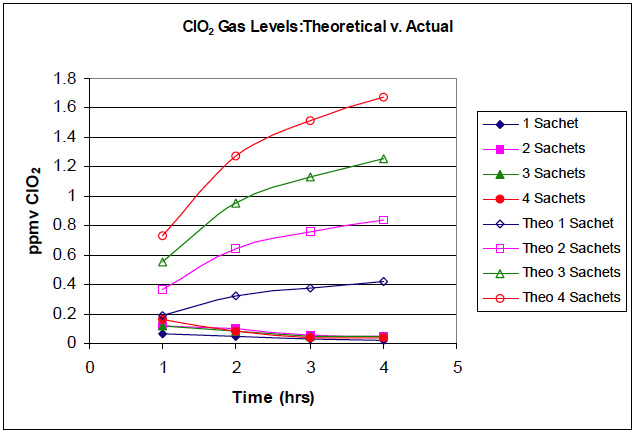

The theoretical ClO2 levels were calculated assuming all ClO2 produced by the sachets accumulate in the room air and is not consumed. The ClO2 generation expected of one sachet was determined by suspending a sachet over 10% KI solution in an enclosed glass container, placing the container in an unlit cabinet and analyzing via titration at 1-hour intervals for four hours. Theoretical and actual ClO2 levels are presented in Figure 5.

Table 1: Average ClO2 levels (ppmv)

| No. Sachets | Time (hr) |

| 1 | 2 | 3 | 4 |

| 1 | 0.07 ± 0.02 | 0.05 ± 0.01 | 0.03 ± 0.02 | 0.02 ± 0.01 |

| 2 | 0.11 ± 0.08 | 0.10 ± 0.08 | 0.05 ± 0.04 | 0.04 ± 0.02 |

| 3 | 0.11 ± 0.07 | 0.10 ± 0.07 | 0.05 ± 0.03 | 0.04 ± 0.02 |

| 4 | 0.16 ± 0.05 | 0.08 ± 0.04 | 0.03 ± 0.03 | 0.03 ± 0.03

|

Figure 4

Figure 5

Discussion

Figure 5 shows that the actual ClO2 levels are well below theoretical values—a phenomenon that can be attributed to the oxidant demand in the treated room as well as decomposition due to the inherent instability of this species and exposure to light.

While Figure 4 suggests that ClO2 concentration in the room is directly proportional to the number of sachets used, the standard deviation of the data indicates otherwise. The data overlap within the confidence interval of one standard deviation demonstrates that the number of sachets used has no considerable impact on ClO2 concentration. The variation in the data can be attributed to fluctuating oxidant demand in the room, inherent degradation factors remaining constant. The change in oxidant demand over time and at different treatment dosages is perhaps an indication that the oxidant demand in the room, although varying, remained at high levels, such that the more ClO2 generated by the sachets, the more consumed.

Conclusions

Multiple air sample analyses of a room treated with StayFresh APS Room “Shock” Deodorizer have demonstrated that this product, in compliance with OSHA’s standards, is safe for use and human exposure. ClO2 is a compound that decomposes readily in gaseous form and when exposed to light. This, along with the oxidant demand normally found indoors, results in a decline in ClO2 levels over time.

Appendix

Table 2: Compilation of data from all experiments: ppmv ClO2

| Exp. No. | Time (hr) |

| 1 | 2 | 3 | 4 |

| 1-a | 0.047 | 0.042 | 0.028 | 0.013 |

| 1-b | 0.089 | 0.063 | 0.031 | 0.022 |

| 1-c | 0.057 | 0.039 | 0.020 | 0.020 |

| 1-d | -- | -- | 0.059 | 0.044 |

| 1-e | 0.073 | 0.038 | 0.013 | 0.009 |

| 2-a | 0.184 | 0.101 | -- | 0.061 |

| 2-b | -- | 0.024 | 0.119 | 0.061 |

| 2-c | -- | 0.039 | 0.018 | 0.033 |

| 2-d | 0.132 | 0.048 | 0.044 | 0.035 |

| 2-e | 0.026 | 0.048 | 0.035 | 0.018 |

| 3-a | 1.057 | 0.235 | 0.054 | 0.053 |

| 3-b | 0.118 | 0.038 | 0.011 | -- |

| 3-c | 0.079 | 0.047 | 0.026 | 0.017 |

| 3-d | 0.219 | 0.105 | 0.057 | 0.053 |

| 3-e | 0.118 | 0.118 | 0.097 | 0.061 |

| 3-f | 0.026 | 0.083 | 0.026 | 0.041 |

| 4-a | 0.097 | 0.039 | 0.012 | 0.007 |

| 4-b | 0.228 | 0.083 | 0.016 | 0.057 |

| 4-c | 0.123 | 0.041 | 0.015 | 0.005 |

| 4-d | 0.158 | 0.097 | 0.051 | 0.032 |

| 4-e | 0.180 | 0.140 | 0.067 | 0.070 |

CHLORINE DIOXIDE ODOR CONTROL PRODUCTS – Maintenance – Shock

General Description

StayFresh APS odor control products safely and reliably release controlled amounts of chlorine dioxide (ClO2). Unlike fragrances, StayFresh APS products actively destroy and absorb odors rather than just covering them up.

StayFresh APS Benefits

- ClO2 is a powerful oxidizer ideally suited for use in Animal Care Facilities.

- ClO2 does not react with ammonia to form chloramines, and it does not form toxic chlorinated organics like seen with chlorine use.

- ClO2, at low dosing, will not harm common materials of construction.

- ClO2 effectively destroys both nitrogen and sulfur based odor compounds associated with decaying flesh, feces, urine, garbage, smoke, musty areas, etc.

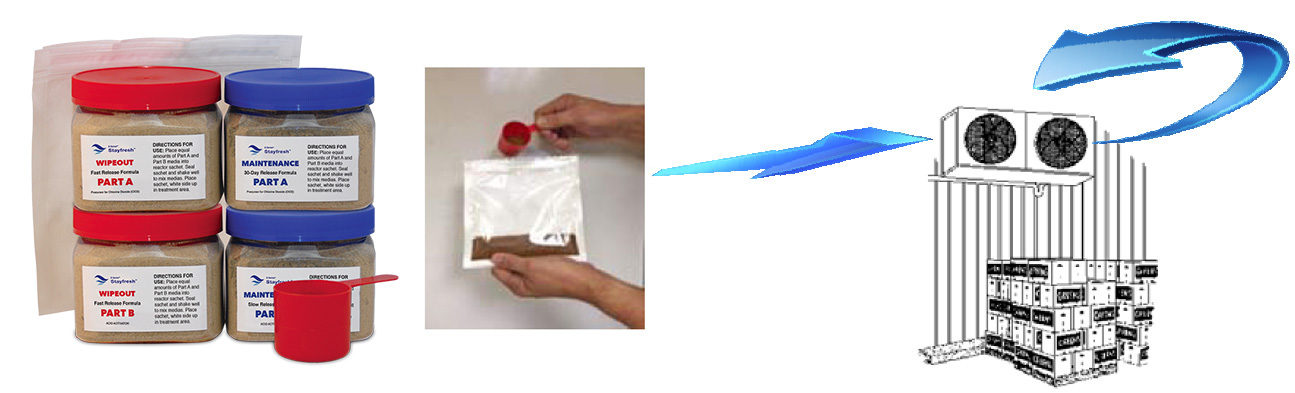

StayFresh APS Application Instructions

The product is activated by pouring equal parts of component A and B into a breathable sachet or tub, securing the zip seal or top, and shaking to mix the components. The StayFresh APS sachet or tub is then placed in the vicinity of your air return venting for your facility air-handler, or in the area closest to a problem odor source. Multiple treatment points should be considered in large facilities. Sachets and/or tubs may also be placed in the vicinity of the air exhaust venting for your facility air handler if this is more convenient, but you lose the added benefit of treating your air-handler when using the product in this manner. Note: different odor problems may demand more or less treatment, and users should expect that some adjustments to the dosing protocol may be required until the appropriate regiment for your facility is determined.

StayFresh APS Maintenance products are used for long-term odor control or light odor demands. StayFresh APS Shock products are used for quicker action on intense odors. Item # 4512 packaged (1 large Maintenance and 1 large Shock)/case.

StayFresh APS Product Activation and Use

The media can be easily applied by pouring the materials directly into the breathable polymer film sachet or tub by opening the sachet, or by unscrewing the top of the tub. The granular media is then added to the sachet or tub, the sachet or tub is sealed, shaken to mix, and put into application. For tub use, after shaking to mix material please be sure to remove the plastic seal covering the top when you activate product so gas can escape and go to work.

The sachets should always be placed with the paper (white) side exposed to the air being moved – facing your air-handler. StayFresh APS will produce an initial mild bleach-like odor on activation. This odor will subside when the product is put into application. If not, the sachet or tub should be moved to a more effective location nearer the odor source or away from the user. In the event that moving the product doesn’t resolve the issue, the dosage should be reduced.

*FOR BEST RESULTS TREAT WITH SHOCK AND MAINTENANCE EVERY MONTH AT THESE RECOMMENDED DOSES*

| Product Type | Product Weight | Release Time (days) | Maximum Air Volume Treatment (cubic feet) |

| StayFresh APS Maintenance * | 9 scoops/jar - (multi-use application) | 30 days | 90,000 |

| StayFresh APS Shock * | 9 scoops/jar - (multi-use application) | 2 days | 90,000 |

Numbers presented in chart are guidelines for application. Actual dosing may vary with environmental conditions and facility design

* Use approximately 1 scoop part A plus 1 scoop part B per 10,000 cubic feet of space being treated

Handling, Storage and Stability

Keep product in tightly closed container when not in use. Do not abrade package on or across hard surfaces. Store in a cool (< 700 F), dry, well-ventilated area away from heat or open flame. StayFresh APS in the original packaging and stored under the above mentioned conditions is stable for up to 24 months from the date of manufacture.

Safety and Health

DO NOT EAT. Product will produce a mild bleach like odor on activation. AVOID DIRECTLY INHALING FUMES. Inhalation of ClO2 gas may cause respiratory irritation. In case of eye contact, flush well with water. Avoid contact with skin. In case of skin contact wash affected area with soap and water. See MSDS sheet for more information.

Revision Date: August 25, 2020